Roy Tomeij :appsignal: · @roy

246 followers · 135 posts · Server ruby.social🎃 Forbidden Donut 🎃 · @toroidalcore

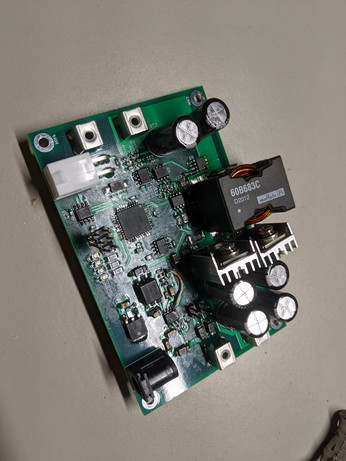

161 followers · 1702 posts · Server hackers.townOkay, everything's installed. I had a few little hiccups, like picking a footprint with the wrong pitch (1.27 mm, needed 2.54 mm) for the programming header, so I got creative and attached a 2.54 mm header I had with wires. I also neglected the courtyard for the big inductor, so it hangs off the board. The two MOSFETs could use a little more space, but at least they're insulated to the heatsinks...

So this thing won't be passing vibe anytime soon. But, so far it seems okay electrically - as in, the housekeeping supply still puts out 5 V, and about 14.2 V for the gate driver. Nothing seems to be pulling it down, like a solder bridge or something. I should be able to get started on programming it, starting with a constant, open-loop PWM signal to the MOSFETs. Then I can look at RS485 comms, and proper control loops.

For those who've only seen bits and pieces of my postings on this, this circuit is just a buck converter. Or a boost converter, in the opposite direction. I just wanted to play around with one, and will probably revise the board in the future.

Basically, it's mean to work with a 12 or 24 VDC nominal bus on the low voltage side, and a 24 or 36 VDC bus on the high voltage side. (In other words, voltage you'd see from a 12, 24, or 36 VDC lead acid battery.) It's mostly to play around, but I intend to add extra logic to make it charge a higher voltage battery from a lower voltage one (or vice versa). Could also be used for photovoltaic maximum power point tracking (MPPT) I guess, but that's not the main intent right now.

#electronics #BuckConverter #PrintedCircuitBoard #kicad6 #PowerElectronics

#powerelectronics #kicad6 #printedcircuitboard #buckconverter #electronics

🎃 Forbidden Donut 🎃 · @toroidalcore

161 followers · 1702 posts · Server hackers.townMy buck converter board finally came. I might start to get this thing assembled this week, at least in stages - I want to make sure the housekeeping supply works (the buck converter that powers the buck converter), then get the microcontroller on. Then get the rest of it together, and maybe move some power.

I should have enough parts to build two of these, assuming I didn't do something horrendous that requires a redesign. Like accidentally build an efficient radio transmitter.

#buckconverter #powerelectronics #electronics #kicad6 #pcb

IT News · @itnewsbot

1661 followers · 238595 posts · Server schleuss.onlineJolly Wrencher SAO, And How KiCad 6 Made It Easy - If you plan to attend Supercon or some other hacker conference, know that you’re g... - https://hackaday.com/2022/10/11/jolly-wrencher-sao-and-how-kicad-6-made-it-easy/ #jollywrencher #featured #interest #inkscape #kicad6.0 #how-to #art #sao #svg

#svg #sao #art #how #kicad6 #inkscape #interest #featured #jollywrencher

🎃 Forbidden Donut 🎃 · @toroidalcore

162 followers · 1702 posts · Server hackers.townOkay, I managed to save some space. There's a couple things I think I want to check footprint-wise, mainly orientation of some diodes.

#electronics #kicad6 #buckconverter

🎃 Forbidden Donut 🎃 · @toroidalcore

162 followers · 1702 posts · Server hackers.townRedoing this board a little bit to make it 100 mm long, down from 120. This is hopefully to save some cash when sending it to fab. There was a lot of unused space anyway.

#buckconverter #electronics #kicad6

🎃 Forbidden Donut 🎃 · @toroidalcore

162 followers · 1702 posts · Server hackers.townSo this board is about 2.5 inches by 5 inches, and will end up being four layers. That includes a main power/signal plane on top, a ground plane, a 5V plane, and an extra signal plane on the back. I haven't started routing it yet, and I may tweak the layout to space things out or make the board a little smaller.

#circuit #buckconverter #kicad6

🎃 Forbidden Donut 🎃 · @toroidalcore

162 followers · 1702 posts · Server hackers.townThe initial glob of components, which can hopefully be turned into a sane layout.

🎃 Forbidden Donut 🎃 · @toroidalcore

162 followers · 1702 posts · Server hackers.townAfter another chunk of procrastination, it's kind of falling into place. Next step is to generate a BOM, then see what parts are unavailable and what to sub for them.

🎃 Forbidden Donut 🎃 · @toroidalcore

162 followers · 1702 posts · Server hackers.townMore work on my buck project in #kicad6. This is actually the housekeeping supply, which is a smaller buck based around a TI LM25018.

Something I had been thinking about for a while was how to get a separate voltage for the gate driver. I need around 5 V for the microcontroller and associated things, and had considered a second converter. It doesn't need to be isolated, it just should be a higher voltage and somewhat steady.

TI has an application note about what they call a Fly-Buck, or isolated buck converter. Basically, you replace the buck inductor with a transformer primary. You regulate the main output as you normally would for the buck converter (selecting the inductance, and in the case of this TI chip picking the right resistors to set the output voltage), and then you can get a second output that's the first times the turns ratio. So I'm giving this a try.

This little supply will take power either from the high voltage side of the main converter it's powering (up to 48 VDC max, for a 24 or 36 VDC battery), or the low voltage side (up to 32 VDC or so for a 12 or 24 VDC battery), or a separate input. I had designed it initially for a 9 V output, to be fed into a linear regulator to get 5 V, but might back off on this. The transformer I picked is 2:1 for turns ratio, so if I go with a 7 V output I can get about 12-13 V or so after diode drop.

🎃 Forbidden Donut 🎃 · @toroidalcore

162 followers · 1702 posts · Server hackers.townWorking on another #buck converter in #kicad6. I have the converter portion done, but of course the real fun is everything that goes along with it. Here is the controller, basically an AVR microcontroller is going to read voltages and inductor current and control the PWM.

The idea is to sense voltage on both sides of the converter, since this should be able to move power in either direction. (In other words, either side can be the input or the output.) Gate drive voltage can be read as well.

Up next is finishing the power supply, and the RS485 communications.