morgan · @morgan

123 followers · 631 posts · Server leds.socialGeekProjects News · @news

4 followers · 3116 posts · Server geekprojects.comIndustrial Robot Gets Open-Source Upgrade https://hackaday.com/2023/05/14/industrial-robot-gets-open-source-upgrade/ #RobotsHacks #controller #industrial #opensource #LinuxCNC #ODrive #Fanuc #gcode #robot #fpga

#RobotsHacks #controller #industrial #opensource #linuxcnc #odrive #fanuc #gcode #robot #fpga

morgan · @morgan

117 followers · 540 posts · Server leds.socialsuper stoked starting on a new contract this week doing some #python #linuxcnc UI work, it's a short one though.....soooo throwing it out there again. I'm interested in lining up my next contract would be interested in things like.....

* pytohn/#Django work

* Embedded C (ESP32/ESP-IDF, nRF/ARM, BLE)

* NodeJS (love highly async, parallel batch processing kind of jobs)

* Early stage devops (you got something running, but deployment/automation is a mess, Docker, LXC/LXD, Ansible automation, etc)

morgan · @morgan

116 followers · 535 posts · Server leds.socialcoooool, starting with debian bookworm #linuxcnc will be installable via apt (I believe) for the first time. This will be very helpful with development, in that I won't have to be in my (still...) cold garage running my nineteen-dickity-doo power hungry server that acts as my CNC controller.

morgan · @morgan

116 followers · 531 posts · Server leds.socialI'm super happy I started tinkering with the #LinuxCNC Python API. It allows for basically unhindered addons, without modification to the core. Now my dust collector is automatic when the spindle starts/stops and I've got a #PixelBlaze reporting job progress!

Stephen Nourse · @san

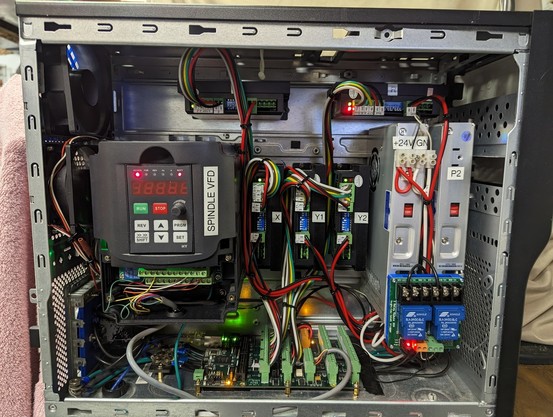

12 followers · 20 posts · Server noc.socialAnother big step. Got the controller for the CNC2 wired up on the bench and powered up - with no magic smoke! Even talks to LinuxCNC the way it's supposed to (via a MESA 7i76e mounted in the bottom). Everything fits in a repurposed computer case. Now to finish the configuration and attach the seemingly 100 wires hanging off the actual unit. #cnc #linuxcnc #maker #cncrouter

#cncrouter #maker #linuxcnc #cnc

Ding Dang Trevor Flowers · @trevorflowers

482 followers · 1749 posts · Server machines.socialBaxEDM switched their EDM machines to #LinuxCNC and Ethercat. Cool!

https://youtu.be/U2BVB2LzUlo

https://www.baxedm.com/

Stephen Nourse · @san

10 followers · 12 posts · Server noc.socialHave come to the conclusion that the only cost effective way to have a fancy control pendant to work with Linuxcnc the way I want is to roll my own. Got the parts coming to do so based on an ESP32. Until then the quick and dirty solution is a cheap USB number pad remapped to the most common Linuxcnc shortcuts. Actually works surprisingly well, jogs, rapid moves, homes, spindle on/off, tool touch off, e-stop, machine power, pause, resume all for under @20. #cnc #cnchacks #linuxcnc #maker

#maker #linuxcnc #cnchacks #cnc

morgan · @morgan

109 followers · 405 posts · Server leds.socialfuck. I don't know how it happened, but the CNC spindle just 'came on' while using #LinuxCNC AXIS. F9/F10 will turn the spindle on but I cannot image how I accidentally hit that while going to F5. Just in case, I'm going to remove the spindle hotkeys but this completely sinks the project I was in the middle of.

I should go drink whiskey in the snow.

morgan · @morgan

109 followers · 405 posts · Server leds.socialfuck. I don't know how it happened, but the CNC spindle just 'came on' while using #LinuxCNC AXIS. F9/F10 will turn the spindle on but I cannot image how I accidentally hit that while going to F5. I think I'm going to go drink whiskey in the snow. Just in case, I'm going to remove the spindle hotkeys but this completely sinks the project I was in the middle of.

morgan · @morgan

108 followers · 383 posts · Server leds.socialAwesome! I did a bunch of reading on the #linuxcnc python API last night and a tidy 37 lines of python later, my dust collector will come on with the CNC spindle

morgan · @morgan

108 followers · 381 posts · Server leds.socialwoooooooow, super glad I found this out while just messing around with #linuxcnc python interface.... but apparently my CNC ESTOP isn't working

morgan · @morgan

106 followers · 358 posts · Server leds.socialMight seem like a small thing but the fact I'm stopping jobs, even resetting #linuxcnc shows I'm getting confident enough in my workflow that think I can resume where I left off without issue. So far so good, I've stopped the job for gcode reload 3-4 times and reset LinuxCNC altogether to increase my max speed.

morgan · @morgan

104 followers · 333 posts · Server leds.socialwhoot! kicking saturday in the butt. Knocked out this long, long over due project. The Sonoff relays cannot handle the inrush current of my dust collector so I got an industrial contactor inline and it's handling it no problem. I made a wifi remote for an old camera that will be repurposed to switching this over #MQTT. I'm hoping I can also script #linuxcnc to also switch it on when ever the spindle is running.

Stephen Nourse · @san

7 followers · 9 posts · Server noc.socialRed letter day today! Installed the X-axis gantry on the CNC2 - and everything fit! All the black "stuff" other than steppers and cable track is all 3d printed in carbon fibre PETG. I figure between using it and what I have learned about 3d printing over a couple of years my parts on this one are probably double the strength of the ones on my original CNC in the background. Z axis to go - and wiring, electronics, programming, etc, sigh.

#CNC #3dprinting #maker #linuxcnc #cncrouter #mpcnc

#mpcnc #cncrouter #linuxcnc #maker #3dprinting #cnc

Stephen Nourse · @san

7 followers · 8 posts · Server noc.socialFinally got my original CNC dialed in for Aluminum. 1/4' two flute carbide 0.5mm cut, 200mm/min works great. No smearing, material stays cool. Working on the X to Y axis plates for my CNC2 build. #CNC #maker #machining #linuxcnc #mpcnc

#mpcnc #linuxcnc #machining #maker #cnc

Trevor Flowers ⚙️⚙️ · @trevorflowers

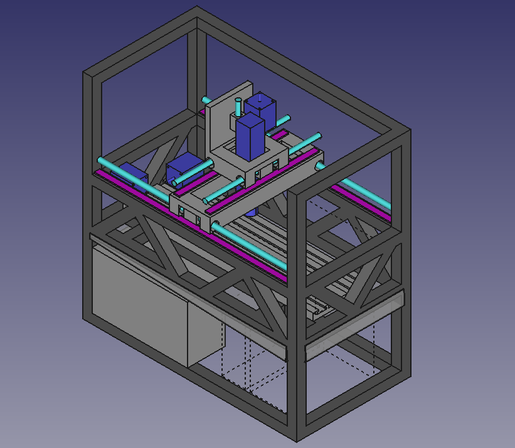

429 followers · 1118 posts · Server machines.social@FreeCAD I'm working this #FreeCADFriday on a new open licensed CNC mill design. Helpful critique on how I'm using #FreeCAD and the machine design itself is very welcome!

Discussion forum is here: https://forum.makerforums.info/t/chela-mill-part-2-the-refininging/86812

The repo is here:

https://codeberg.org/Transmutable/chela-mill

#machining #DIYCNC #LinuxCNC

#linuxcnc #diycnc #machining #freecadfriday #freecad

Trevor Flowers ⚙️⚙️ · @trevorflowers

425 followers · 1069 posts · Server machines.socialI started a thread on Maker Forums about an open hardware design for a home shop CNC mill that is designed to cut steel. It's called the Chela Mill. Many details are still TBD so if you're experienced with (or interested in) machine tool design then I'd love to see you weigh in, here or in the forum.

https://forum.makerforums.info/t/chela-mill-part-2-the-refininging/86812

#machining #DIYCNC #CNC #ChelaMill #FreeCAD #LinuxCNC

#linuxcnc #freecad #chelamill #cnc #diycnc #machining

Trevor Flowers ⚙️⚙️ · @trevorflowers

414 followers · 1039 posts · Server machines.socialOne step closer to using a FOSS CNC controller to make atoms move.

#machining #DIYCNC #ChelaMill #LinuxCNC

#linuxcnc #chelamill #diycnc #machining

Stephen Nourse · @san

7 followers · 6 posts · Server noc.socialDuring the base assembly on my CNC2 project (a smaller, stiffer build) I realized I could easily add a vacuum hold down system to it. There were already holes in the bed for the hold down system and the rails underneath naturally divided things into sections. All I needed to add was some blocking, a bottom and some valving - et voila! The amazing thing is it actually works well. Next, machining the side plates to mount the X axis.

#cnc #maker #linuxcnc #cnchacks #3dprinting #cncrouter

#cncrouter #3dprinting #cnchacks #linuxcnc #maker #cnc