copypasteninja · @copypasteninja

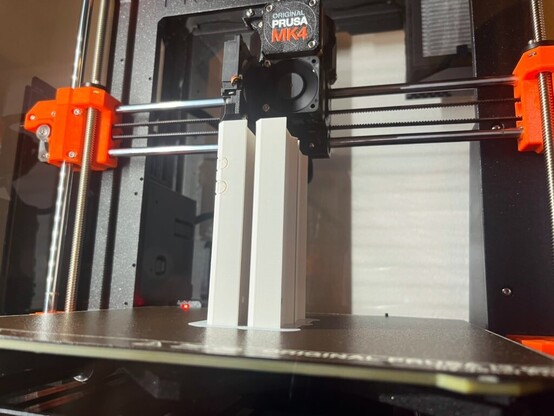

8 followers · 23 posts · Server norden.socialAdded home printed MNT Reform Anti-Flexing Bars to a Reform. #mntreform #prusa3d

The Homespun Days · @thehomespundays

220 followers · 1292 posts · Server triangletoot.partyI think the #carolina weather has ruined my PLA. So many failed prints where there were almost none before. #prusa3d #3dprinting

#3dprinting #prusa3d #carolina

Commodore Sixty Bore · @sikkdays

831 followers · 4468 posts · Server ourempty.pubcopypasteninja · @copypasteninja

1 followers · 16 posts · Server norden.socialSecond build for work done :awesome: #mechanicalkeyboard #diy #prusa3d

#mechanicalkeyboard #diy #prusa3d

Justin D Kruger (he/him) · @jdavidnet

77 followers · 380 posts · Server me.dm@lytta I looked at Cura, but I don’t know it as well. I couldn’t find as many bridge and infill settings.

I might make a feature request for #PrusaSlicer to allow you to modify the settings I’d like to have. #Prusa3d has been good in the past about evaluating new possible features.

Yurko Tymchuk · @uko

2 followers · 56 posts · Server masto.tymch.ukYurko Tymchuk · @uko

2 followers · 53 posts · Server masto.tymch.uk

Andy Piper · @andypiper

3144 followers · 3070 posts · Server macaw.socialDan KE8SMQ · @ke8smq

37 followers · 79 posts · Server mastodon.hams.socialSo close...

geekandi · @geekandi

20 followers · 310 posts · Server tooting.cc@Stark9837 @Zorzal @andy_warb @3dprinting

Speaking of #prusa #prusa3d delays..

https://www.reddit.com/r/prusa3d/comments/12m501x/lots_of_frustration_on_xl_day_one_preorder/

It's just me whining and making a passive/aggressive stance on bait & switch (which I use those words, so maybe not so P/A)

Rob Ludwick · @RobLudwick

32 followers · 149 posts · Server mstdn.socialSo the reason I'm interested in this is because #Prusa3d seems to do a really good effort to dogfood their 3d printers -- using them in their own production facility, etc.

The MMU2s wasn't shown a lot of love apparently, and what I was hoping for was the MMU3 to be dogfooded as well in their production facility.

The text appears to be raised plastic (not paint).

That's why I think Prusa is using a stamped sheet since the rest of the part looks like it's been printed on a textured sheet.

Rob Ludwick · @RobLudwick

35 followers · 176 posts · Server mstdn.socialSo the reason I'm interested in this is because #Prusa3d seems to do a really good effort to dogfood their 3d printers -- using them in their own production facility, etc.

The MMU2s wasn't shown a lot of love apparently, and what I was hoping for was the MMU3 to be dogfooded as well in their production facility.

The text appears to be raised plastic (not paint).

That's why I think Prusa is using a stamped sheet since the rest of the part looks like it's been printed on a textured sheet.

Rob Ludwick · @RobLudwick

32 followers · 145 posts · Server mstdn.socialI wonder if #prusa3d made a special steel sheet for the logos, basically stamping the logo into it.

Some custom gcode could fill the stamps with colors and then they could print the standard part on top of it, fusing the plastic together.

The logo is "raised" and doesn't appear to be evenly distributed.

Rob Ludwick · @RobLudwick

35 followers · 176 posts · Server mstdn.socialI wonder if #prusa3d made a special steel sheet for the logos, basically stamping the logo into it.

Some custom gcode could fill the stamps with colors and then they could print the standard part on top of it, fusing the plastic together.

The resulting logo is "raised" and doesn't appear to be evenly distributed.

Rob Ludwick · @RobLudwick

32 followers · 144 posts · Server mstdn.socialRob Ludwick · @RobLudwick

35 followers · 176 posts · Server mstdn.socialDeckerEgo · @deckerego

25 followers · 173 posts · Server fosstodon.orgAfter stabbing myself in the thigh I figured there was a better way to carry around a hand weeding tool than loose in my shorts. Built a weed trowel (is that it?) clip w/ Blender and a Prusa MINI+ before I stab something else... ⛏️🩳

https://www.printables.com/model/451104-hand-weeder-lawn-mower-mount

Didier Lüthi :verified: · @luthi

85 followers · 210 posts · Server tooting.chOriginal Prusa MK4 is here: Always perfect first layer, high-speed printing with Input shaper, 32-bit platform, Nextruder, MMU3. SHIPPING NOW! - Original Prusa 3D Printers

#prusa3d #3dprinter #josephPrusa

https://blog.prusa3d.com/announcing-original-prusa-mk4_76585/

#josephprusa #3dprinter #prusa3d

Robee? Na! 🌈 · @RobeeShepherd

149 followers · 1517 posts · Server mastodon.artNow fitted with some printed parts to my Prusa mini! If this doesn’t stop the z lead screw wobbling (it looks straight when I take it off, it only wobbles in situ) I’m just going to sit in the corner and whimper a bit

Michael Gebis · @IvyMike

4 followers · 26 posts · Server infosec.exchangeNinjaflex gasket designed and printed... and after around 15 hours of failed prints, it works! #3dprinting #prusa #prusa3d #ninjatek #ninjaflex

#3dprinting #prusa #prusa3d #ninjatek #ninjaflex