Justin D Kruger (he/him) · @jdavidnet

77 followers · 380 posts · Server me.dm@lytta I looked at Cura, but I don’t know it as well. I couldn’t find as many bridge and infill settings.

I might make a feature request for #PrusaSlicer to allow you to modify the settings I’d like to have. #Prusa3d has been good in the past about evaluating new possible features.

Justin D Kruger (he/him) · @jdavidnet

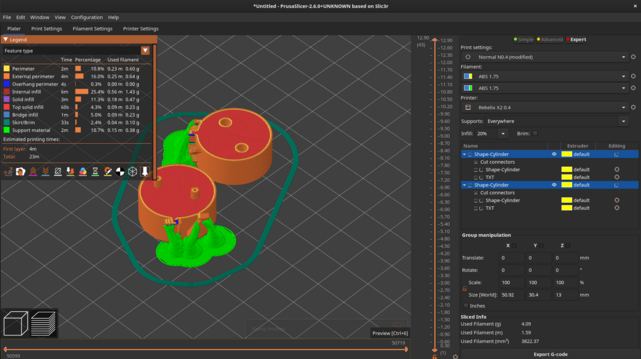

77 followers · 375 posts · Server me.dmI am trying to print this file, on #Printables

And a few cm from the top it starts adding bridge infill, solid infill, extra perimeters, or other changes that negatively impact the print quality as the angle of the lines shift slightly.

I wish I could just turn these features off, or change the extrusion multiplier over time.

I'm not sure what else to try to improve print quality.

#3dprinting #prusaslicer #printables

3D Printing · @3dprinting

429 followers · 1134 posts · Server techhub.social🖥️ Slicers, the heart of 3D printing!

🚀 Which one is your ultimate choice? Are you a fan of #Cura's simplicity, enjoying #PrusaSlicer's comprehensive features, or perhaps jumping aboard the hype train for the up-and-coming #OrcaSlicer? Or maybe you prefer the classic path with vanilla #BambuSlicer?

Cast your vote and share your slicer preferences with the community! Let's find out which slicer reigns supreme! 🗳️🎉

#cura #prusaslicer #orcaslicer #bambuslicer #3dprinting #slicerwars #slicingsoftware

Icchan :debian: :raspberrypi: · @Icchan

7 followers · 37 posts · Server mastodon.unoFriendship ended with #UltimakerCura. Now my best friend is #PrusaSlicer

#3dprinting

#ultimakercura #prusaslicer #3dprinting

Andi · @wildbird

2 followers · 9 posts · Server aut.socialKeine Ahnung was das genau wird, aber diese neuen Supports vom #prusaslicer schauen genial aus an dem Teil.

#prusaslicer #3ddruck #3dprinting #prusa #happylab

Štěpán Škorpil :skorpil_cz: · @stepan

486 followers · 924 posts · Server mastodon.skorpil.czJust noticed that new #PrusaSlicer version 2.6 got into #ArchLinux package repository.

It has several important new features:

🔌 You can place knobs to a horizontal cut to easilly align pieces when glueing them

🏗 It has new "organic" support structure

⌨ It can add text to the object surface (cut, emboss or as modifier)

The Chantelier · @chantelier

21 followers · 58 posts · Server writing.exchangeSettings/tricks involved: #firstlayer is printing at an undemanding 15mm/s, the temperature is a balmy 240c with an 90c bed temp, which will ramp down to 235/80 for the remainder of the print. The hotbed is spring-steel, with four coats of VO5's "Firm Hold" hair spray, for a lustrous shine and bounce. The printer is an Ender 3v2, and tonight is wearing a beautiful Biqu H2S Revo with a 0.6mm nozzle. Her filament is #petg by X3D. Doesn't she look stunning! #3dprinting #prusaslicer #ender3

#ender3 #prusaslicer #3dprinting #petg #firstlayer

stark@techhub.social:~$ █ · @Stark9837

397 followers · 2111 posts · Server techhub.socialI wish #Prusa allowed for native plugins and a similar marketplace for #PrusaSlicer. Imagien if we could have native support for slicing modifications and processing rather than post-processors, which can get quite complicated.

#prusa #prusaslicer #3dprinting

stark@techhub.social:~$ █ · @Stark9837

397 followers · 2111 posts · Server techhub.socialI am really enjoying #OrcaSlicer. I've printer probably 30 hours with it.

I created my profile by copying over my #PrusaSlicer profile, but actually found it not to work as good, so I tweaked it and found that there is a clear difference in extrusion rates. My OrcaSlicer profile uses 0.98 extrusion multiplier and PrusaSlicer 1.06, with other values also being different.

I don't know how to put my finger on it. But looking at a part, I decide which I am going to use to slice it, and it always comes out good.

It won't be replacing PrusaSlicer anytime soon for me, but it is now another tool in my arsenal.

#orcaslicer #prusaslicer #3dprinting

#PrusaSlicer オーガニックサポート試してみた。めっちゃ光造形感ある。あと上に向かって広がるからこういう下にモデルがあったりサポート面がでかい形状には最適 #3Dプリンター #3Dprinting https://pawoo.net/media/j7KdztY1zHgpQSnEzPY

#3dprinting #3dプリンター #prusaslicer

Rep Rap Ryn :3 · @reprapryn

167 followers · 386 posts · Server fosstodon.org#system76 just got my new Adder WS and now starting the long arduous task of downloading all my crap to it. Steam is going to take days to download everything I want it to play

Do got #freecad and #prusaslicer installed already so in the interim can do some 3d printer related stuff.

This should have enough Moxy to eat FEM for lunch, I can start doing physics optimization for alot of designs

#system76 #freecad #prusaslicer

MaryPot · @MaryPot

171 followers · 3478 posts · Server masto.aiIs there some way I can set a setting in ALL my configurations (Upper left eg. 0.20 mm NORMAL SPEED etc) at once?

The slicer has grid as default for all the different settings, but MY default is organic - for example.

So I want all the presets I have in my library to be preset to organic.

MaryPot · @MaryPot

171 followers · 3478 posts · Server masto.aiGetting a tad snobbish about how my prints look.

Does it hurt the print to wet sand the seam?

I figure not, but worry about the thickness of the outer layer being compromised. I print plant pots, and they REALLY shouldn't leak! 😁

stark@ubuntu:~$ █ · @Stark9837

338 followers · 1835 posts · Server techhub.socialThe other thing is. With #PrusaSlicer in the printer's custom #Gcode where you set the start, end,layer-change, etc. Gcode. You can access variables such as temperature and layers, etc.

You, however, can't access variables like acceleration limits and use those values to emit them to your Macros when you run #Klipper.

So I need to look at a print, think a bit. Set limits in Klipper, transfer said limits to #PrusaSlicer, generate gcode, and then print.

#OrcaSlicer actually will honor your request to print slower or faster, but there is something wrong with its flow rate.

If you slice an object and switch to the flow-rate view. The color codes clearly show that it exceeds your set max. However , in speed-view, you can see that the speed is correct. And in #Mainsail during printing and can actively see how it changes the acceleration limits as it prints overhangs, perimiters, and briges.

As you can see, I am between 2 slicers here

#prusaslicer #gcode #klipper #orcaslicer #mainsail #3dprinting

stark@ubuntu:~$ █ · @Stark9837

338 followers · 1835 posts · Server techhub.socialUnfortunately, I stopped caring about the acceleration limits and everything in #PrusaSlicer since I started to run #Klipper because it actually tells you that the limits are only for time predictions and aren't Ctually emitted to #Gcode.

But when you use #OrcaSlicer and you insert custom accelerations and dynamic-overhang-speeds and limits, the printer actually honors it.

So, not only are my time predictions with OrcaSlicer more accurate, but I am actually printing at the rate that I want to and chose in the slicer.

But then finally, I have to say. OrcaSlicer does not honor flow-rate limits as well as PrusaSlicer does. If I tell PrusaSlicer to never exceed 12mm^3/s, it would slow itself down.

OrcaSlicer justs YOLOs itself past that limit, and my exteuders start to skip!

#prusaslicer #klipper #gcode #orcaslicer #3dprinting

DeFrisselle ☑️ · @defrisselle

359 followers · 13421 posts · Server mastodon.sdf.orgAndreas G. · @guddl

66 followers · 368 posts · Server social.anoxinon.dePrusaSlicer 2.6 is out. https://www.prusa3d.com/page/prusaslicer_424/ #PrusaSlicer #3DPrinting #prusa #3ddruck

#prusaslicer #3dprinting #prusa #3ddruck

Darknet-NG · @DarknetNG

22 followers · 12 posts · Server defcon.socialNew Video on Darknet-NG 12 Default Badge & Slicer Use https://youtu.be/6PKa7aMCKIw #darknet #badge #PrusaSlicer #DEFCON #badgelife

#darknet #badge #prusaslicer #defcon #badgelife

AJ Venter · @metalpoetnl

74 followers · 604 posts · Server metalhead.club@pezhore @opsitive a few smaller things I actually compiled from source so I could override the install targets into homedir based paths.

I use #CURA for 3D printing slicing and that has a flatpack so that's nice.

But I want to get a Prusa MKIV in a year or so, and then I'lll probably want to switch to #prusaslicer which doesn't. That could be interesting to solve.

MaryPot · @MaryPot

164 followers · 3262 posts · Server masto.aiCan someone figure out why hubby's Gcodes from Prusa Slicer do not include bed levelling a the start of every print, but mine do?

Both using V 2.6.0-beta2+win64

Tried searching for "level" in the slicer, but none of the hits seemed relevant.