Mr.Trunk · @mrtrunk

10 followers · 16642 posts · Server dromedary.seedoubleyou.meTheOnion: Bleeding 9-Year-Old Asks To Go To Slaughterhouse Nurse https://www.theonion.com/bleeding-9-year-old-asks-to-go-to-slaughterhouse-nurse-1850752438?utm_source=regular #animalslaughter #slaughterhouse #humaninterest #blainewilkins #meatindustry #meatslicer #slicer #aband #meat

#animalslaughter #slaughterhouse #humaninterest #blainewilkins #meatindustry #meatslicer #slicer #aband #meat

IT News · @itnewsbot

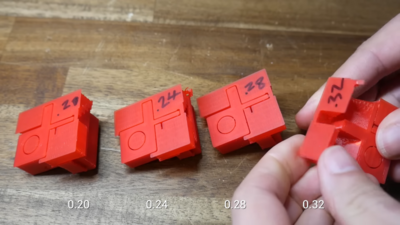

3489 followers · 266675 posts · Server schleuss.onlineOrca Slicer Is The New Game In Town - Slicers are the neat little tools that take your 3D models and turn them into G-co... - https://hackaday.com/2023/07/13/orca-slicer-is-the-new-game-in-town/ #3dprinterhacks #3dprinting #orcaslicer #slicer

#slicer #orcaslicer #3dprinting #3dprinterhacks

Geert Bevin · @gbevin

774 followers · 975 posts · Server uwyn.netOrca Slicer is becoming a great contender as the best slicer for me, starting to replace Simplify3D with it. https://github.com/SoftFever/OrcaSlicer #3Dprinting #3dprint #slicer

stark@ubuntu:~$ █ · @Stark9837

307 followers · 1680 posts · Server techhub.social

CellBioNews · @cellbionews

49 followers · 1129 posts · Server scientificnetwork.deNovel #genetic manipulation technique can help scientists make the most of #radiation-resistant #bacterium.

#Deinococcus #SLICER #DNA #deletion

https://phys.org/news/2023-04-genetic-technique-scientists-radiation-resistant-bacterium.html

#genetic #radiation #bacterium #deinococcus #slicer #dna #deletion

stark@ubuntu:~$ :idle: · @Stark9837

283 followers · 1519 posts · Server techhub.socialSo companies are only gibing us #opensource where they must or need to by law, but if all of them opted in to use #CAN bus for all communication, it would be much simpler.

We also need to formally define generic and known sensors, similar to #Klipper, to allow an iser to easily mod and change their setup to something else without modifying the firmware too much.

#BambuLabn #Slicer was also attempted to be kept closed and sourced until they had to release it duebtonlicensing with #Prusaslicer, which in turn gave us OrcaSlicer

I promise you the #BambuLab #AMS won't be compatible with any othernprinter.

#opensource #can #klipper #bambulabn #slicer #prusaslicer #bambulab #ams

stark@ubuntu:~$ :idle: · @Stark9837

280 followers · 1484 posts · Server techhub.socialAnother great tip, is actually lower the resolution of your slicer. Because it doesn't use G3 movements, it will only result in cutting of circles into even smaller 100s or 1000s of straight lines.

You'll see great improvement and reduction in bulges by just doing this alone, because such resolution isn't required and the #Slicer often uses a high resolution better suited to newer and 32-bit boards.

stark@ubuntu:~$ :idle: · @Stark9837

280 followers · 1476 posts · Server techhub.social#PrusaSlicer is by far the best #Slicer that I've used in my 3 years of #3dprinting. My profiles are dell tuned and I have my entire workflow set up in it.

#Cura is very user friendly in the sense that it hides many settings. It's like the #TinkerCAD of slicers.

#SuperSlicer is the original fork of #PrusaSlicer, but I like the support I am getting now.

#prusaslicer #slicer #3dprinting #cura #tinkercad #superslicer

stark@ubuntu:~$ :idle: · @Stark9837

262 followers · 1428 posts · Server techhub.socialNo, not really.

Remember, a #Slicer such as #PrusaSlicer is only for converting the 3D object from a design file to the paths that the #3dprinter must print. So you can't do stuff like that because you want to modify the file.

What you can, however, do is slter the model a bit in the slicer with modifiers. You can create a box in #PrusaSlicer and then subtract it from the object, cutting off a corner of the object.

But you are ideally looking for a chamfer or fillet in the design.

#slicer #prusaslicer #3dprinter #3dprinting

stark@ubuntu:~$ :idle: · @Stark9837

244 followers · 1305 posts · Server techhub.socialThere are so many variables in 3D printing! I often forget #slicer settings when I am printing and only realise it halfway through prints. The best solution I got was using #PrusaSlicer and the great profiles that you can set up for it and all of your materials, allowing you to always load your saved profile.

I also have a checklist for common things I forget when printing!

#slicer #prusaslicer #3dprinting

stark@ubuntu:~$ :idle: · @Stark9837

244 followers · 1296 posts · Server techhub.socialI also have problems with organic supports going through my prints. I printed something which needed supports, and the organic supports when through my piece, a part which was supposed to be hollow.

Normally this wouldn't be a problem, but I was printing a fan duct, so I needed that part to be hollow.

#3dprinting #prusaslicer #slicer

stark@ubuntu:~$ :idle: · @Stark9837

243 followers · 1293 posts · Server techhub.social#PrusaSlicer Alpha 6 is out.

There is not improved support for #Klipper #firmware and also improved #Gcode variables. The variables and G-code improvements could be interesting and I will look into them.

Otherwise most of it is mostly background stuff.

One thing I did notice is the remove of "Infill only when needed". It was actually a feature I used without any problems and it actually helped to speed up my prints quite a lot, but apparently I was one of few and it actually had a lot of bugs.

Full changelog here: https://github.com/prusa3d/PrusaSlicer/releases

#prusaslicer #klipper #firmware #gcode #3dprinting #prusa #slicer #3dprinter #3dprint #update

phranck :next: · @phranck

950 followers · 2164 posts · Server swiftdev.spaceDie Moeglichkeit im #BambuStudio mehrere Druckplatten anzulegen, und gleich alle Teile als ein Projekt abzuspeichern, das ist schon fein.

#bambustudio #bambulab #3ddruck #3dprinting #slicer

IT News · @itnewsbot

3038 followers · 254110 posts · Server schleuss.onlineA Comprehensive Look at FDM Supports - When we first started 3D printing, we used ABS and early slicers. Using supports w... - https://hackaday.com/2023/03/27/a-comprehensive-look-at-fdm-supports/ #3dprintedsupports #supportmaterial #3dprinterhacks #3dprinting #slicer

#slicer #3dprinting #3dprinterhacks #supportmaterial #3dprintedsupports

GeekProjects News · @news

4 followers · 3116 posts · Server geekprojects.comA Comprehensive Look at FDM Supports https://hackaday.com/2023/03/27/a-comprehensive-look-at-fdm-supports/ #3Dprintedsupports #supportmaterial #3dPrinterhacks #3dprinting #slicer

#3dprintedsupports #supportmaterial #3dPrinterhacks #3dprinting #slicer

stark@ubuntu:~$ :idle: · @Stark9837

208 followers · 1139 posts · Server techhub.socialFirst we need to cut the bottom off the model, otherwise the bottom is too thick and wasteful.

We can do this in #PrusaSlicer easily, no 3D editing required, the #slicer can do it.

#3dprinting #prusaslicer #slicer

stark@ubuntu:~$ :idle: · @Stark9837

203 followers · 1122 posts · Server techhub.socialIf it is a .stl file, you would need to set the temperatures manually, .stl files are only models.

If it is a .3mf file, the creator could set the temperatures in a #slicer like #PrusaSlicer, because .3mf files are more flexible and have more features.

Lucky Resistor · @luckyresistor

90 followers · 73 posts · Server mastodon.artThe latest alpha version (2.6.0-alpha5) of PrusaSlicer finally fixes the issue with the vertical shell thickness. 🎉😄

Instead of small rectangular fill patterns that cause vibrations, it uses a concentric fill pattern. It not only creates better results but is also way faster to print because fewer direction changes are required.

The same frame print of my modular lantern is over one hour faster and the result looks better.

#slicer #improvement #alpha #prusaslicer #prusa

Haus ohne Schornstein · @Kirmesboxer

77 followers · 271 posts · Server mastodon.pub.solarHmmh, der #Elegoo kommt mit der 0.6er #Nozzle überhaupt nicht klar. #Slicer-Einstellungen sind angepasst, Layerhöhen und -breiten auch. Verschiedene Temperarturen an der Nozzle und am Druckbett habe ich ausprobiert. Ich denke, dass wird was mit dem Flow sein, das muss ich mal irgendwann in Ruhe machen.

Jetzt ist wieder die 0.4er drauf und alles ist gut.

#3dprinting

#elegoo #nozzle #slicer #3dprinting

Stark · @Stark9837

97 followers · 649 posts · Server techhub.socialWhich slicer are you using to slice it? Have you tried the new tree-supports in Prusa Slicer?

#3dprinting #slicer #prusaslicer